Working Stress Design Method And Its assumptions with Limitations

Working Stress Design Method Definition:

Working Stress Design Method is a method used for the reinforced concrete design where concrete is assumed as elastic, steel and concrete act together elastically where the relation ship between loads and stresses is linear .

Assumptions of Working Stress Design Method

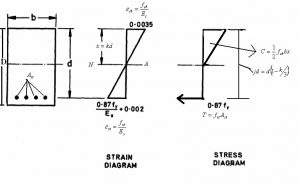

- Plane Section before bending will remain plane after bending

- Bond between steel and concrete is perfect with in elastic limit of steel

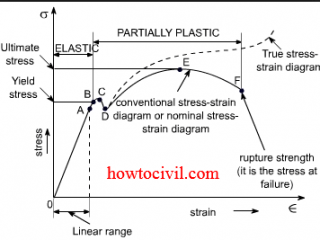

- The steel and concrete behaves as linear elastic material

- All tensile stresses are taken by reinforcement and none by concrete

- The stresses in steel and concrete are related by a factor known as “modular ratio

- The Stress-strain relationship of steel and concrete is a Straight line under working load

Limitations of working stress method :

- The assumptions of linear elastic behaviour and control of stresses within specially defined permissible stresses are unrealistic due to several reasons viz., creep, shrinkage and other long term effects, stress concentration and other secondary effects

- Different types of load acting simultaneously have different degrees of uncertainties. This cannot be taken into account in the working stress method

- The actual factor of safety is not known in this method of design. The partial safety factors in the limit state method is more realistic than the concept of permissible stresses in the working stress method to have factor of safety in the design.

IF anyone need to take credit please comments below .Thanks

i want prosses of solving the problems

I need materials of r16 regulation ddrcs one to six units as per jntuk plz send it to my mail.tq u sir

This is good as required 😌☺️ l am happy because of the point it is written.

Thanks for sharing